Call Us08045800108

Water Treatment Chain

100 INR/Piece

Product Details:

- Features High Durability, Smooth Operation, Easy Maintenance

- Thickness 5-15 mm Chain Link

- Surface Finish Polished

- Belt Type Plastic/SS Slat Chain

- Power Source Electric Motor Driven

- Material Stainless Steel

- Type Water Treatment Chain Conveyor

- Click to view more

X

Water Treatment Chain Price And Quantity

- 10 Piece

- 100 INR/Piece

- 100-800 mm Customized

- Adjustable as per design

- Self-lubricating bushings

- <65 dB

- 60C

- Floor Mounted, Fixed

- Double Strand Industrial Chain

- 25.4 mm (standard)

Water Treatment Chain Product Specifications

- Variable, up to 10 m/min

- Polished

- Water Treatment Chain Conveyor

- Water Treatment Plants, Effluent Treatment Process, Industrial Filtration Systems

- 5-15 mm Chain Link

- High Durability, Smooth Operation, Easy Maintenance

- Chain Type Equipped

- Corrosion and Rust Resistant

- Up to 1000 kg per meter

- 2-5 HP

- Heavy Duty Steel Frame

- Not equipped

- Plastic/SS Slat Chain

- Stainless Steel

- 220-240 V

- Electric Motor Driven

- 100-800 mm Customized

- Adjustable as per design

- Self-lubricating bushings

- <65 dB

- 60C

- Floor Mounted, Fixed

- Double Strand Industrial Chain

- 25.4 mm (standard)

Water Treatment Chain Trade Information

- 100 Piece Per Day

- 3 Days

Product Description

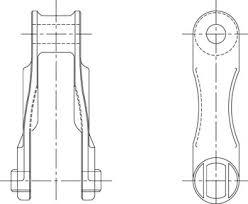

BWC-Type Chain

| Type | Description |

| BWC-Type Water Treatment Chain | Used with Water Treatment Screens |

TWS/RBS-Type BDP600R

- Used with various water treatment facilities

- The link plate is made from rolled structural steel (SS) and pins, bushes, and rollers are comprised of 400-Series stainless steel.

- Corrosion and abrasion resistance is excellent to protect against seawater and air particles due to the application of BDPA and BDEE paint to both the top and bottom of the chain

- Use special grease (BDPS-500) on the rollers inner diameter so that water can act as a lubricant.

| Type | Description |

| TWS/RBS BDP600R | Improvements to BWC-Type Water Treatment Chains lUses BDPS-500 Grease Uses BDPA-1184 Primer Uses BDEE-173 (top coat) paint. |

Adaptable Design for Water Treatment Needs

Our water treatment chain conveyors are built with customization in mind. With adjustable discharge height, chain widths ranging from 100 to 800 mm, and chain link thickness options, clients receive tailored solutions. The double strand configuration and heavy-duty steel frame ensure consistent and reliable operation even in demanding settings.

Optimized Performance and Energy Efficiency

Designed to manage loads of up to 1000 kg per meter, our conveyor operates efficiently with a variable speed mechanism and power range of 2-5 HP. The polished stainless steel finish, together with corrosion and rust resistance, guarantees long-term performance while minimizing maintenance needs in harsh industrial environments.

Quiet and Smooth Operations for Industrial Environments

Powered by electric motors and enhanced by self-lubricating bushings, this equipment remains exceptionally quiet, maintaining noise levels below 65 dB. The smart engineering ensures smooth chain movement, reducing operational disturbances in water treatment facilities and supporting a productive work area.

FAQs of Water Treatment Chain:

Q: How is the Water Treatment Chain Conveyor installed?

A: The conveyor is designed to be floor mounted and comes as a fixed installation. Our team provides commissioning support and guidance, ensuring seamless integration into your facility based on project-specific discharge heights and layouts.Q: What materials are used in the construction and why?

A: The main structure utilizes heavy-duty steel with stainless steel polished surfaces and slat chain belts in plastic or SS. These materials provide high durability, resistance to corrosion and rust, and ease of maintenance in water-rich industrial settings.Q: When should I select a double strand industrial chain?

A: Double strand industrial chains are chosen for applications requiring greater strength, load capacity (up to 1000 kg per meter), and enhanced stability, making them ideal for demanding water treatment and filtration processes.Q: Where can this conveyor system be used?

A: Our Water Treatment Chain Conveyor is suited for water treatment plants, effluent treatment processes, and various industrial filtration systems, offering reliable bulk material handling and disposal.Q: What is the process for customizing the chain width and discharge height?

A: Clients can specify their preferred chain width (between 100 and 800 mm) and discharge height during the design phase. Our team collaborates closely with customers to tailor these aspects for their particular applications and facility requirements.Q: What are the key benefits of using this chain conveyor in water treatment applications?

A: Key benefits include high durability, smooth and quiet operation, adjustable and customizable features, minimal maintenance due to self-lubrication, and superior load capacityall essential for efficient industrial water treatment operations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Water Treatment Chains' category

We are mainly dealing in brands like Omega, Rexnord.

|

INDUS MARKETING ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send SMS

Send SMS