Call Us08045800108

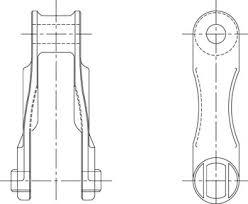

Driving Chain

100 INR/Piece

Product Details:

- Power Source Mechanical

- Features High strength, precision construction, reliable operation

- Surface Finish Polished

- Thickness Standard/Custom

- Material Alloy Steel

- Type Driving Chain

- Structure Chain Drive

- Click to view more

X

Driving Chain Price And Quantity

- 100 INR/Piece

- 10 Piece

- Wooden box / carton packaging

- Depends on chain size and design

- Standard & custom sizes available

- Regular lubrication recommended

- -20°C to 180°C

- Heat-treated steel

- Hardened, wear-resistant

- Zinc plated / Self colored / Blackodized

Driving Chain Product Specifications

- Industrial power transmission, conveyor systems, material handling equipment

- Standard/Custom

- Varies by application

- Corrosion Resistant

- Alloy Steel

- Polished

- Customizable as per requirement

- Chain Drive

- Driving Chain

- Mechanical

- High strength, precision construction, reliable operation

- Wooden box / carton packaging

- Depends on chain size and design

- Standard & custom sizes available

- Regular lubrication recommended

- -20°C to 180°C

- Heat-treated steel

- Hardened, wear-resistant

- Zinc plated / Self colored / Blackodized

Driving Chain Trade Information

- 100 Piece Per Day

- 3 Days

Product Description

Redeem the reliability of the latest and most sought-after Driving Chain, engineered for monumental efficiency and ineffable strength. Available in both standard and custom sizes, these top-tier chains boast a robust structure and a breaking load capacity tailored to your requirements. Each link is forged from heat-treated alloy steel, coupled with hardened pin & bush assemblies, ensuring wear resistance and unmatched durability. The zinc-plated, blackodized, or self-colored finish guarantees corrosion resistance. Precision construction, regular lubrication, and customizable designs make these chains ideal for industrial power transmission, conveyor systems, and material handling. Distributed globally from India by leading manufacturers, exporters, and traders.

Broad Application Spectrum for Driving Chains

Driving Chains are not limited to industrial power transmission; they excel in a wide range of applications such as conveyor systems and automated material handling equipment. Their mechanical power source and polished alloy steel construction ensure both strength and longevity. The chains are perfect for both standard and custom requirements, and the high-strength materials impart exceptional reliability. Their corrosion resistance and precision engineering make them a universally sought-after component for demanding operational environments.

Packaging, Transportation & Domestic Market Details

Each Driving Chain is delivered securely packed in wooden boxes or carton packaging for safe transportation and seamless handling. Our well-coordinated logistics network ensures timely delivery and the products are handed over in pristine condition. With substantial supply ability, we meet the demands of the expanding domestic market in India. Every unit is carefully packaged to withstand the rigors of transport, safeguarding against damage and ensuring customer satisfaction throughout the domestic mar and export channels.

Broad Application Spectrum for Driving Chains

Driving Chains are not limited to industrial power transmission; they excel in a wide range of applications such as conveyor systems and automated material handling equipment. Their mechanical power source and polished alloy steel construction ensure both strength and longevity. The chains are perfect for both standard and custom requirements, and the high-strength materials impart exceptional reliability. Their corrosion resistance and precision engineering make them a universally sought-after component for demanding operational environments.

Packaging, Transportation & Domestic Market Details

Each Driving Chain is delivered securely packed in wooden boxes or carton packaging for safe transportation and seamless handling. Our well-coordinated logistics network ensures timely delivery and the products are handed over in pristine condition. With substantial supply ability, we meet the demands of the expanding domestic market in India. Every unit is carefully packaged to withstand the rigors of transport, safeguarding against damage and ensuring customer satisfaction throughout the domestic mar and export channels.

FAQs of Driving Chain:

Q: How do I determine the correct chain size for my application?

A: Selecting the right chain size involves evaluating your applications load requirements, speed, and operational environment. Custom sizes are also available to suit specific needs. Reach out to our technical team for expert guidance.Q: What material features make this Driving Chain suitable for industrial use?

A: The chain is crafted from heat-treated alloy steel, equipped with hardened, wear-resistant pins and bushes. This construction delivers high strength, excellent durability, and exceptional corrosion resistance, ideal for demanding industrial environments.Q: Where can Driving Chains be used apart from power transmission?

A: Besides industrial power transmission, these Driving Chains find use in conveyor systems, material handling equipment, and automated assembly lines, thanks to their robust design and adaptability.Q: What are the packaging and delivery options for Driving Chains?

A: Driving Chains are available with wooden box or carton packaging, ensuring they are well-protected during shipping. Our logistics network guarantees prompt and secure delivery, both domestically and for export.Q: How often should the Driving Chain be lubricated for optimum performance?

A: Regular lubrication is recommended to ensure smooth operation, reduce wear, and extend the service life of the chain, especially in high-load or high-speed applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Water Treatment Chains' category

We are mainly dealing in brands like Omega, Rexnord.

|

INDUS MARKETING ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send SMS

Send SMS