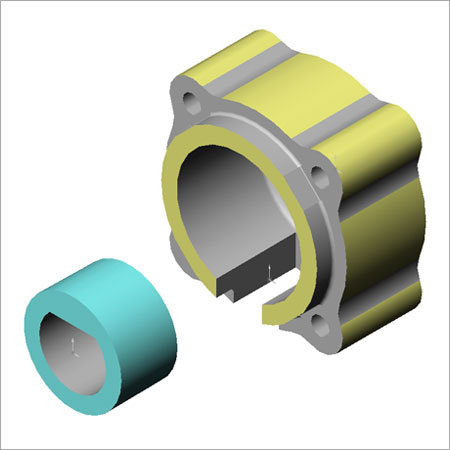

Ni Hard Bearing

100 INR/Piece

Product Details:

- Precision Rating P5

- Inside Diameter 50 mm

- Thickness 40 mm

- Lubrication Type Grease

- Retainer Steel

- Cage Material Steel

- Bearing Type Cylindrical Roller Bearing

- Click to view more

X

Ni Hard Bearing Price And Quantity

- 100 INR/Piece

- 100 Piece

- Excellent

- Yes

- -20°C to 180°C

- Press Fit

- Heavy Industrial Equipment

- 58-64 HRC

- Smooth Polished

- Silver

Ni Hard Bearing Product Specifications

- 2

- Steel

- Open

- 1800 RPM

- Steel

- High

- Double Row

- Cylindrical Roller Bearing

- P5

- 110 mm

- 50 mm

- Ni Hard (Nickel Hard Iron)

- 40 mm

- 50 mm

- Grease

- Excellent

- Yes

- -20°C to 180°C

- Press Fit

- Heavy Industrial Equipment

- 58-64 HRC

- Smooth Polished

- Silver

Ni Hard Bearing Trade Information

- 100 Piece Per Day

- 3 Days

Product Description

Since 2003, we have been manufacturing, exporting and supplying excellent quality Ni Hard Bearing for our clients in various sizes and dimensions. This bearing is installed in various bikes and trolleys to ensure high speed transmission of mechanical force. The provided bearing is manufactured by our diligent professionals using quality-approved raw materials and sophisticated techniques. Apart from this, we offer this Ni Hard Bearing to our client at the most economical price.

Features:

- Excellent finish

- Self alignment

- Withstand high load

- Dimensionally accurate

Superior Durability and Hardness

Ni Hard Bearings are crafted from advanced Nickel Hard Iron, providing a hardness of 58-64 HRC. This ensures enhanced resistance to wear and deformation under intense, continuous loads. The smooth polished finish not only increases aesthetic appeal but also improves operational performance in heavy-duty applications.

Engineered for Industrial Demands

Optimized for heavy industrial equipment, these bearings operate efficiently in a wide temperature range (-20C to 180C) and offer outstanding resistance to corrosion. The double-row, cylindrical roller design, combined with a high load capacity and shock load resistance, makes them a dependable choice for rigorous conditions.

FAQs of Ni Hard Bearing:

Q: How does the Ni Hard Bearing perform under extreme shock loads?

A: Thanks to its Ni Hard (Nickel Hard Iron) construction and double-row cylindrical roller design, the bearing exhibits excellent shock load resistance, making it ideal for applications where sudden or heavy impacts are frequent.Q: What are the primary benefits of using Ni Hard Bearings in heavy industrial equipment?

A: These bearings offer high load capacity, superior hardness (58-64 HRC), corrosion resistance, and stable performance in temperatures ranging from -20C to 180C, ensuring reliability and reducing maintenance in demanding machinery.Q: When should I choose a double-row cylindrical roller bearing with a 50 mm bore size?

A: Select this bearing for applications requiring robust radial load support, higher rigidity, and a compact solution for shafts with a 50 mm diametercommon in presses, conveyors, and heavy-duty machines.Q: Where are Ni Hard Bearings commonly used?

A: These bearings are primarily employed in heavy industrial environments across India and globally, finding usage in mining equipment, steel mills, conveyors, and manufacturing plants where durability and shock resistance are crucial.Q: What is the recommended process for installing these bearings?

A: The Ni Hard Bearing is designed for press-fit mounting. Ensure precise seating by using the appropriate tools and follow standard industrial procedures to avoid damage during installation.Q: How does using grease lubrication benefit the Ni Hard Bearings performance?

A: Grease lubrication minimizes friction and protects the bearing surfaces, enhancing operational life and ensuring consistent performance, especially when combined with the bearings open seal and robust design.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'BEARING HOUSING' category

We are mainly dealing in brands like Omega, Rexnord.

|

INDUS MARKETING ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send SMS

Send SMS