Call Us08045800108

SD SERIES PLUMMER BLOCKS

100 INR/Piece

Product Details:

- Lubrication Type Grease/Oil Lubrication through Provision

- Precision Rating Standard (DIN/ISO specifications)

- Cage Material Steel or Brass (Depending on Bearing)

- Retainer Integrated in Bearing Design

- Thickness As Per Standard SD Series Dimensions

- Inside Diameter Compatible with Bearing Bore, matches Shaft Size

- Bearing Type Self-aligning, Spherical Roller or Ball Bearings

- Click to view more

X

SD SERIES PLUMMER BLOCKS Price And Quantity

- 100 INR/Piece

- 100 Piece

SD SERIES PLUMMER BLOCKS Product Specifications

- 35 mm to 100 mm

- Cast Iron or Cast Steel

- Double Lip, Felt, or Labyrinth

- Steel or Brass (Depending on Bearing)

- Standard (DIN/ISO specifications)

- Grease/Oil Lubrication through Provision

- Single

- Depends on Bearing and Housing Size

- Self-aligning, Spherical Roller or Ball Bearings

- Plummer Block Housing

- Standard as per SD Series Size Chart

- Compatible with Bearing Bore, matches Shaft Size

- Heavy Duty, Application Dependent

- Integrated in Bearing Design

- As Per Standard SD Series Dimensions

SD SERIES PLUMMER BLOCKS Trade Information

- 100 Piece Per Day

- 3 Days

Product Description

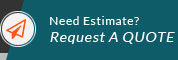

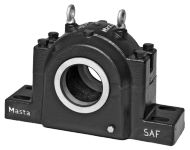

Experience the unassailable performance of SD SERIES PLUMMER BLOCKS, an ephemeral opportunity to seize a renowned solution, now offered at a special rate. Trusted across industrial machinery sectors, these foot-mounted blocks feature a world-class paint-coated finish, exceptional corrosion resistance, and extraordinary vibration dampening. Engineered for heavy and shock loads, with standardized interchangeability and robust cast iron or steel housing, they accommodate multiple seals and lubrication types. Pick yours from an extensive rangeensuring flawless compatibility with various bearings and shaft sizesfor enduring operational supremacy.

Exceptional Performance & Robust Material

SD SERIES PLUMMER BLOCKS set a benchmark in bearing housing technology. Designed using premium cast iron or steel, these blocks deliver high durability and are ideally suited for applications that demand resilience under heavy and shock loads. With a paint-coated surface to enhance corrosion resistance, the world-class construction upholds reliability even within harsh industrial workflows. These blocks are perfect for heavy-duty usage, offering a competitive advantage in terms of longevity and vibration resistance.

Global Certifications & Efficient Market Coverage

Our SD SERIES PLUMMER BLOCKS are certified to meet DIN and ISO standards, ensuring uncompromised quality. We supply and dispatch these valiant solutions across main export markets including Asia, the Middle East, and Africa, while maintaining a robust distribution network within India. Our dispatching process prioritizes timely handover for both domestic and international customers, underlining our commitment as an exporter and supplier to deliver excellence swiftly and reliably.

Exceptional Performance & Robust Material

SD SERIES PLUMMER BLOCKS set a benchmark in bearing housing technology. Designed using premium cast iron or steel, these blocks deliver high durability and are ideally suited for applications that demand resilience under heavy and shock loads. With a paint-coated surface to enhance corrosion resistance, the world-class construction upholds reliability even within harsh industrial workflows. These blocks are perfect for heavy-duty usage, offering a competitive advantage in terms of longevity and vibration resistance.

Global Certifications & Efficient Market Coverage

Our SD SERIES PLUMMER BLOCKS are certified to meet DIN and ISO standards, ensuring uncompromised quality. We supply and dispatch these valiant solutions across main export markets including Asia, the Middle East, and Africa, while maintaining a robust distribution network within India. Our dispatching process prioritizes timely handover for both domestic and international customers, underlining our commitment as an exporter and supplier to deliver excellence swiftly and reliably.

FAQs of SD SERIES PLUMMER BLOCKS:

Q: How do I select the correct SD SERIES PLUMMER BLOCK for my application?

A: You should consider your machinerys required load capacity, bore size, type of bearing, and the operating temperature range. Consult the SD Series size chart to select the perfect match for your shaft and machinery specifications.Q: What types of seals are available with SD SERIES PLUMMER BLOCKS?

A: These plummer blocks can be equipped with double lip, felt, or labyrinth seals. The choice depends on your specific operating environment and the level of contamination protection needed.Q: Where can SD SERIES PLUMMER BLOCKS be used?

A: They are ideally used in industrial machinery, particularly where equipment endures heavy loads, shock impacts, and frequent vibrationsuch as conveyors, mining, and material handling systems.Q: What process is involved in mounting SD SERIES PLUMMER BLOCKS?

A: Mounting involves securely placing the foot-mounted block to the machine base, aligning the bearing with the shaft, and ensuring proper lubrication through the provisioned grease or oil channels. Always follow manufacturers installation guidelines to maximize performance.Q: What are the benefits of choosing these world-class blocks?

A: The main benefits include exceptional corrosion resistance, high vibration resistance, standardized interchangeability, and the ability to carry heavy and shock loads, ensuring a longer service life and reliable operation in demanding industrial environments.Q: When should grease or oil lubrication be used in these blocks?

A: The choice between grease and oil lubrication depends on the application speed, operating temperature, and maintenance interval requirements. Refer to your equipments specifications and the bearing manufacturers recommendations for the optimal lubrication method.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'BEARING HOUSING' category

We are mainly dealing in brands like Omega, Rexnord.

|

INDUS MARKETING ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send SMS

Send SMS