Axle Box Cylindrical Roller Bearing

100 INR/Piece

Product Details:

- Cage Material Brass / Steel

- Lubrication Type Grease Lubrication

- Precision Rating P0/P6 (Standard/High Precision)

- Retainer Cylindrical Brass/Steel Cage

- Inside Diameter 130 mm

- Thickness 31 mm

- Bearing Type Axle Box Bearing

- Click to view more

X

Axle Box Cylindrical Roller Bearing Price And Quantity

- 100 INR/Piece

- 100 Piece

- Low

- Standardized for rail industry use

- Low

- Press Fit

- 375 kN

- -40°C to +120°C

- 470 kN

- Corrosion resistant polished finish

- Railway Wagon and Coach Axle Boxes

Axle Box Cylindrical Roller Bearing Product Specifications

- 130 mm

- Cylindrical Brass/Steel Cage

- Up to 2500 rpm

- 31 mm

- Double Row

- Axle Box Bearing

- High Load (suitable for Axle Box applications)

- Brass / Steel

- Grease Lubrication

- 220 mm

- High Carbon Chromium Steel

- 130 mm

- P0/P6 (Standard/High Precision)

- Cylindrical Roller Bearing

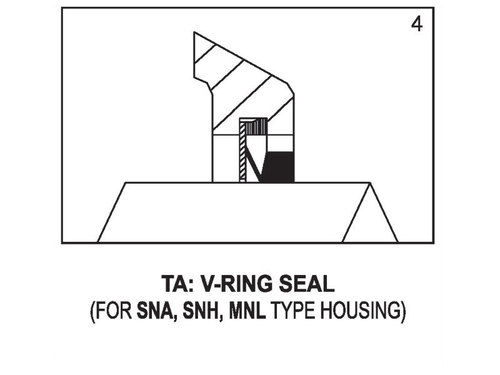

- Open / No Seals

- Low

- Standardized for rail industry use

- Low

- Press Fit

- 375 kN

- -40°C to +120°C

- 470 kN

- Corrosion resistant polished finish

- Railway Wagon and Coach Axle Boxes

Axle Box Cylindrical Roller Bearing Trade Information

- 100 Piece Per Day

- 3 Days

Product Description

To satisfy specific preferences of our clients, we have been manufacturing, exporting and supplying excellent quality Axle Box Cylindrical Roller Bearing in different diameters. This bearing is suitable for countless aerospace and naval machinery that works under high load and high speed. The provided bearing is precisely manufactured by our deft professionals using excellent quality raw materials and pioneering techniques. Additionally, we are offering this Axle Box Cylindrical Roller Bearing to our clients at pocket friendly prices.

Features:

- Dimensional accuracy

- Corrosion and abrasion resistance

- Rugged design

- High angular movement

Engineered for Rail Industry Demands

These cylindrical roller bearings are specifically tailored for railway wagon and coach axle boxes, supporting heavy loads and enduring extreme temperature variations. Their standardized dimensions ensure compatibility and streamlined maintenance across rail fleets, making them an ideal choice for safety-critical rail environments.

High Performance and Durability

Crafted from high carbon chromium steel with a corrosion-resistant polished finish, this bearing delivers robust strength and longevity. The double-row design, open structure, and advanced cage materials minimize vibration and noise, while high load ratings and a press-fit mounting method guarantee stable, reliable performance.

FAQs of Axle Box Cylindrical Roller Bearing:

Q: How is this cylindrical roller bearing mounted in railway axle box applications?

A: The Axle Box Cylindrical Roller Bearing is designed for press-fit installation into axle boxes of railway wagons and coaches, ensuring secure placement and efficient load transfer during operation.Q: What benefits does a double-row structure provide in axle box bearings?

A: A double-row structure offers enhanced radial load capacity, stability, and improved resistance to misalignment. This is especially beneficial in high-demand rail environments where consistent, reliable performance is crucial.Q: When should these bearings be chosen for railway applications?

A: These bearings should be used when a high load capacity, low vibration, and low noise solution is needed for axle boxes, especially where interchangeability, standard compliance, and robust temperature resistance are essential.Q: Where are these bearings typically supplied and installed?

A: Primarily used in railway wagons and coaches, these bearings are supplied across India and internationally, and are installed in locomotive maintenance facilities and rail vehicle manufacturing plants.Q: What is the recommended lubrication process for this bearing?

A: It is advised to use grease lubrication when installing the bearing. Proper application ensures smooth rotation, reduces wear, and extends the operational life of the bearing.Q: How does the absence of seals affect usage requirements?

A: Being open (without seals), the bearing allows for straightforward inspection and regular re-lubrication, making it suitable for controlled environments or where external seals and effective lubrication schedules are maintained.Q: What are the key benefits of using this bearing in rail applications?

A: This bearing provides high load capacity, delivers reliable operation in extreme temperatures, minimizes vibration and noise, and features standardized sizing for easy interchangeability, enhancing the efficiency and safety of rail operations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Bearings' category

We are mainly dealing in brands like Omega, Rexnord.

|

INDUS MARKETING ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send SMS

Send SMS